Recently updated on: September 4th, 2025

Have you ever wondered how coconut oil is actually made? I recently had the opportunity to visit a coconut oil workshop along the Kenyan coast, where I observed the full process from the moment the coconuts arrive, to the final stages of pressing and packaging the oil.

What I saw was a method that combines hands on work with simple machinery, all guided by natural processes. From sorting and opening the coconuts to solar drying and cold pressing, each step is handled with care and purpose. The entire experience gave me a deeper appreciation for how much effort and thought goes into producing pure, cold pressed coconut oil.

In this article, I will share my observations from the visit, how the process works step by step and how sustainability is part of the daily operation.

Step 1: Sourcing and Cleaning the Coconuts

Everything starts with fresh, mature coconuts, collected from surrounding farms in the region. These coconuts are sourced directly from small scale farmers. Once they arrive at the facility, the coconuts are thoroughly washed to remove any dirt. A drilling machine is then used to make small holes in each coconut to extract the coconut water. The water is bottled and immediately placed in cold storage, as it can spoil within just a few hours if not refrigerated.

Step 2: Extracting the Coconut Flesh

After draining, the coconuts are manually cracked open. Inside, the white coconut flesh is carefully removed using hand tools. This part of the process is done by skilled workers to ensure the coconut meat remains clean and intact.

Step 3: Solar Drying the Coconut Flesh

The fresh coconut meat is then taken to a solar tunnel dryer, a sustainable drying system powered by sunlight and natural airflow. The drying period ranges from one to three days depending on the weather. Interestingly, the dryer continues to work efficiently even when the sun is not shining directly, making the system both reliable and eco friendly.

Step 4: Cold Pressing the Oil

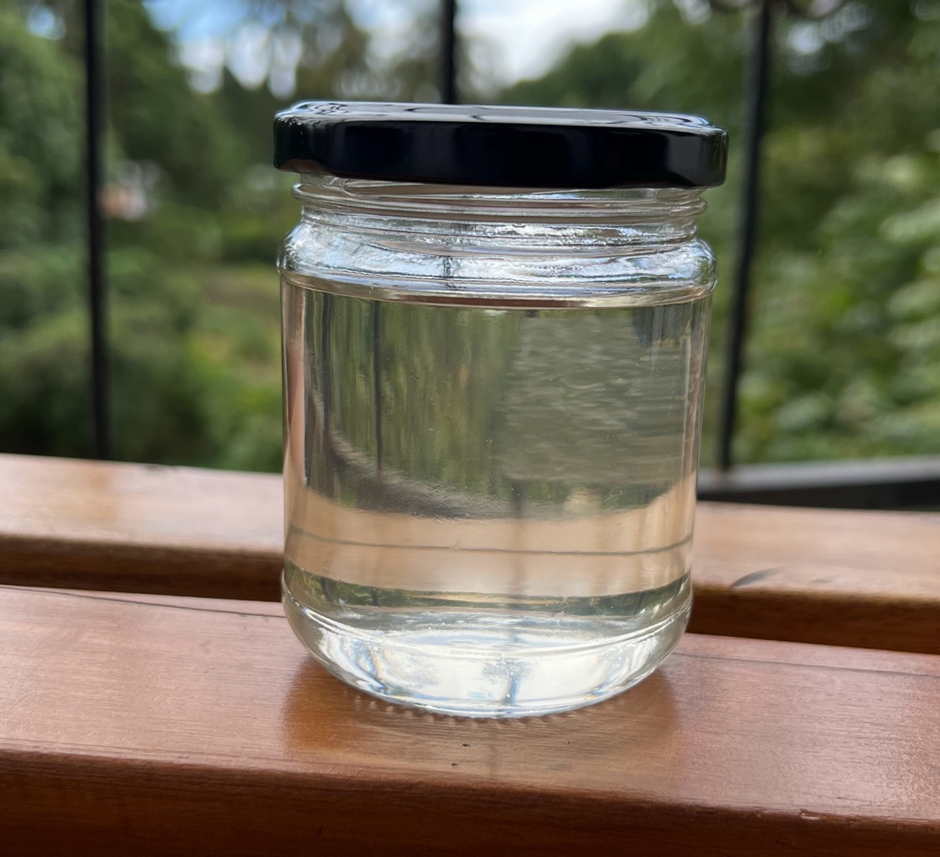

Once the coconut flesh is properly dried, it’s transferred to a cold press machine. This is where the oil is extracted without the use of heat or chemicals. Cold pressing helps retain the coconut’s nutrients, natural aroma, and golden clarity. The oil that comes out is rich, clean, and unrefined.

Coconut oil

High-quality VIRGIN COCONUT OIL – wholesale distributor. Coconut oil is used in the pharmaceutical and cosmetic industries.

The product is safe and does not irritate the skin. In cosmetic products, it acts as a solvent for other substances. In addition, it moisturizes and softens the skin. Coconut oil is semi-solid, white in color, and has a characteristic coconut scent.

After pressing, the oil is allowed to settle naturally before being filtered. The filtering process removes any small particles, resulting in smooth, pure cold-pressed coconut oil. No preservatives, bleaching agents, or additives are used at any stage.

Step 5: Use of By-products

What impressed me most about the visit was how the factory ensures that no part of the coconut is wasted. After oil extraction, the remaining fiber known as copra cake is sold to farmers as poultry feed. The hard coconut shells are either converted into charcoal or used in crafts and decor, while the husk is repurposed in the textile industry to make doormats, brushes, and rope. It’s a practical, sustainable system that supports local communities and reduces waste.

Observations from the Visit

I was struck by how seamlessly traditional knowledge and sustainable practices were working together. The workers showed skill, focus, and pride in their work, and every step felt thoughtfully designed to protect the quality of the oil and the environment.There was a sense of purpose and connection both to nature and to the people involved in the process. It’s a kind of production that honors the ingredient from start to finish.

What I experienced was more than a production process , it was a story of care, community, and sustainability. Seeing how cold pressed coconut oil is made gave me a fresh appreciation for this everyday product and for the people who create it with so much dedication. If you have ever used coconut oil in your cooking, skincare, or hair routine, this is where it begins: with a coconut, the sun, and people who truly value natural, ethical production.